Automated Label Applicators The Magic of Automated Systems Complesity to Simplicity in labeling IntroductionLabeling is an inline process that should be automated as possible. But what if you could tag your products in seconds? Enter: The automated label applicator. Did you know that these magnificent machines make your labeling effort hassle-free, faster, streamlined and not to mention significantly reduces human error? A label applicator is an essential machine when it comes to the fields of manufacturing and retail.

Several benefits are provided by Automated label applicators. 1) It saves you precious time An automated label applicator, for example is capable of labeling your products many times faster than manually appliedintools. It allows you to label hundreds of products in matter minutes - a marked improvement over manual labelling. Second, automated label applicators are highly accurate. Their work envelopes the labels in exactly one position every time making it safe from errors. Automated label applicator marking is more efficient than manual tagging. They do not get tired or commit errors. It enables you to tag your products much faster and, more importantly, in a very precise manner.

In short, automated label applicators are a marvel of technology. Bolstered by the newest materials and technology, these systems are as sturdy & reliable. It accepts a broad parameter of label sizes and materials (small to large, simple to complex designs). The label applicators advancements have helped in producing labels fantastically faster than one could ever imagine.

Automated label applicators are equipped with numerous safety features to lower the risks of injuries. For one thing, their sensors will detect anything that might be standing in the way. They stop by themselves if they run into anything in their path, thus eliminating accidents., Automated label applicators come equipped with warning signs and alarms that let the operator know if something goes wrong. All of these devices are the must to keep your work environment safe.

Automated Label Applicator In Action Install the Applicator and Load Your Labels properly. It is achieved using either a template or printing marks on the product. Next, you load the applicator with labels of choice (you need to make sure they are aligned). After that, turn on your applicator and begin the process of labeling. The control panel allows you to set the speed and position of your labels. Just unplug the applicator when you are all done and Load any left over labels.

It pertains to the Service and Quality of Automated Label Applicators

They Are Made to Last Automated label applicators can take abuse from hot or cold environments. Designed with the best raw materials and components, these disc springs are trusted for their robust build. But in case, your applicator happens to even have a slight trauma, service team of most manufacturer do provide all kind of help and support. This might range from spare parts to even technical assistance, or training your employees. Quality Service and Aftercare to Maintain the Performance of Your Labeling Processes

Automated label applicator: can provide more competitive prices due scale effects direct control production costs. Also hope can your ideal partner especially bulk orders long-term relationships. High production control capacity: factory able directly manage process production making simpler adjust to needs specifications. Direct control assures quality products prompt delivery tailor-made requirements. Flexibility factories swiftly adapt their production processes meet personalized customer needs. believe clients come first very proud ability listen to fully understand requirements. expert research development staff, as well specialized mold workshop, allow us respond quickly efficiently requests customization. We'll everything we meet goals clients. Care about after-sales services provide. We available whenever anything help with.

company conducts debugging prior when equipment can shipped. company provide operation instructions related technical information demand side docking personnel. will arrange technicians respond questions client regarding equipment. Automated label applicator will assigned answer various questions about operation maintenance equipment. Tech support provided phone support remote support, field support

design must be Automated label applicator applicable national standards regulations contracts guarantee highest quality equipment. make sure equipment accessories provided meet requirements agreement. In order keep up modern era, actively research develop new product upgrade existing ones. create better social value, reflect efficient rigorous working style company, reduce customer concerns.

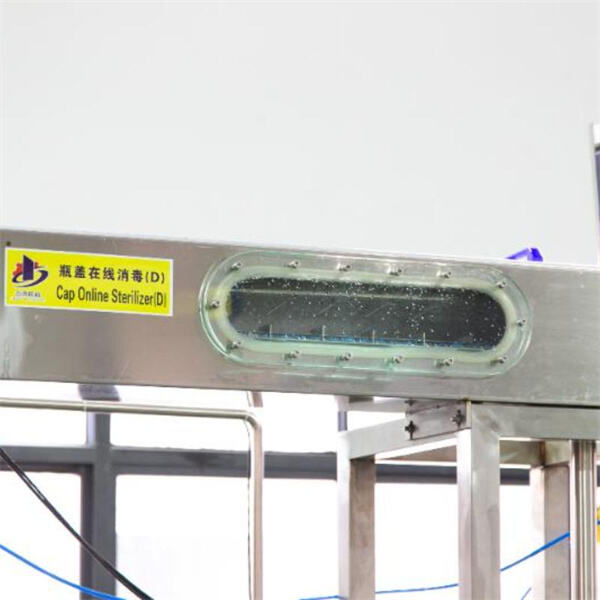

We reputable complete line water filling line Automated label applicator production line producers offering professional beverage equipment beverage filling equipment, pure water filling line mineral water filling machine, small-sized water production line juice filling machines, gas beverage equipment, complete set carbonated beverage filling equipment.

Applications of Automated Label Applicators For food packing, cosmetics or pharma industry labels can be used almost anywhere. He found these printers to be great for mass production lines, especially when accuracy along with speed matters and when dealing with products required specific controls as well as the need of labeling them comprehensively for example barcodes, warnings or ingredients lists. It does not matter what your business type is — be it a manufacturer, retailer or distributor — an automatic label applicator will always save you time and automate things in the best possible way. Being in the label industry, it is one of the new tools for anybody who renders labeling. The automated label applicators Whether you need to speed up your labeling operations, reduce mislabeling risk or increase the safety of label application automatic labeling can help. The devices are user friendly, deliver excellent service, and can be applied across a multitude of industries. You can make your type of labelling fast just within 10 seconds with an automated label applicator and increase the overall efficiency level in a business.

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy