Juice or beverage filling machines, sanitation is crucial. This equipment processes the food people ingest everyday, yes drink and if it is not clean, germs grow and make you sick. Juice and drinks can go bad fast if the equipment is dirty.

What Are The Top Hygiene Tips for Juice and Beverage Filling Machinery

I’m sure keeping juice and beverage filling equipment clean is far more than just wiping it down. It has to be done carefully in order to prevent germs from multiplying and mixing with the beverages. First, all the components that touch the juice will need to be cleaned after every use. That would be getting all the remaining juice out of there, and rinsing with water to remove sugars and pulp.

Where to Get Trustworthy Sanitation Solutions for Your Wholesale Juice Filling Machines

It is not easy to select cleaning products and equipment for juice filling machines. Many companies claim to have a product that works well, but not all are safe or effective when used on large machines. At Jiede, we specialize in sanitary solutions that are designed specifically for industrial juice and beverage equipment. Our cleaning chemicals are proven strong on germs and gentle on machine parts. This balance prevents damage and prolongs the life of machines.

The Impact of Sanitation on the Shelf Life and Safety of Wholesale Juice

Sterilization is very crucial in the process of juice and other drink, particularly for filling machines. These are the machines that put juice in bottles or containers. And if theyre dirty, small germs can crawl and dirt can work its way into the juice. This can render the juice undrinkable and more prone to spoilage. Germs that grow in juice can make people sick if they drink it.

What Wholesale Buyers Should Know About Cleaning Beverage Filling Machines

Wholesale purchasers, those individuals who buy juice in quantity often, should be aware of the necessity to clean beverage liquid filling machine frequently. These machines touch juice and bottles constantly, they can pick up germs, leftover juice and dirt. If cleaning is inadequate, these can combine with new juice to render it unsafe.

Where to apply Sanitation Controls on Juice/Beverage Filling Lines

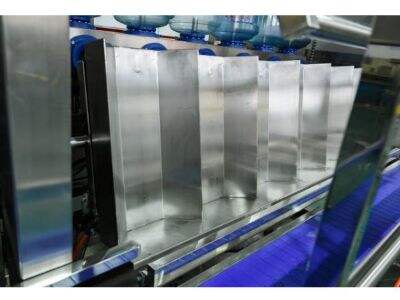

Sanitation controls are the steps and procedures a company takes to bottle filling machine ensure that its juice making process is clean and safe. These controls must be located in multiple strategic locations along the juice and beverage fill line.

Conclusion

This must be a dry, cool and clean place to keep the juice fresh. Last but not least, the programs for inspection and cleaning should be documented in writing and strictly adhered to by everyone who sets foot in the building. Jiede water filling machine helps by designing machines to be readily cleaned and offering recommendations on what should be cleaned, when and how.

Table of Contents

- What Are The Top Hygiene Tips for Juice and Beverage Filling Machinery

- Where to Get Trustworthy Sanitation Solutions for Your Wholesale Juice Filling Machines

- The Impact of Sanitation on the Shelf Life and Safety of Wholesale Juice

- What Wholesale Buyers Should Know About Cleaning Beverage Filling Machines

- Where to apply Sanitation Controls on Juice/Beverage Filling Lines

- Conclusion

EN

EN

AR

AR

BG

BG

HR

HR

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

SQ

SQ

GL

GL

TH

TH

MS

MS

BE

BE

HY

HY

BN

BN

BS

BS

MR

MR

NE

NE

KK

KK

SU

SU

TG

TG

UZ

UZ

KY

KY

XH

XH