The modern filling plant is the place where fresh water is filtered and bottled. Step one, the water comes from a clean source water, from perhaps a river or well. Then it gets filtered to remove any dirt or germs. After that, it’s given a special chemical treatment to ensure that it is potable. At last, the water is bottled and chicks tightened.

Water bottling plants provide clean, and safe drinking water to the public by adhering to the rigorous purification procedures and rules set forth by the FDA. At Jiede, for instance, we have a group of experts who test the water daily to ensure it is safe. We also ensure that our water filling plant is clean and in good working condition.

The path that water follows at a water filling machine begins with the water being pumped from its source to the plant. Then filtered into pipes to clean the water. From there, it is treated with certain chemicals to render it potable. Eventually, the water is bottled and labeled with the Jiede logo.

PF - 10 L Quality control and clean in the water filling plant is a big concern. In Jiede, we have professionals who ensure that the water is good for consumption. We also clean our water filling bottle machine and ensure it is in good working condition. This is to guarantee that whatever water we’re bottling is best in quality.

Waste and energy is cut too at the water filling stations. In Jiede, we do our best to recycle our waste. We also utilise smaller energy-saving equipment to lessen the amount of energy we use. This is good for the environment and keeps resources for the future.

Before delivering equipment equipment shipped, company completed debugging. company provides operating instructions well as technical information docking personnel Water filling plant side. We make arrangements technicians answer questions asked customers regarding equipment. Technicians answer queries regarding maintenance operation equipment. Technical support can provided: telephone support; remote support field support.

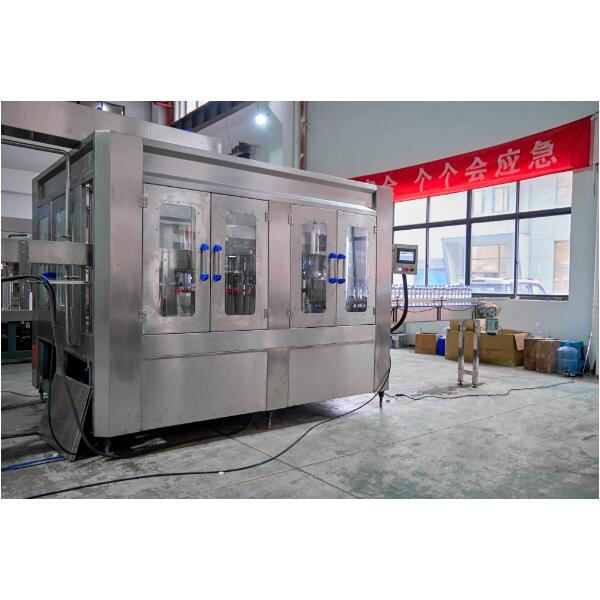

Water filling plant: can provide more competitive prices due scale effects direct control production costs. Also hope can your ideal partner especially bulk orders long-term relationships. High production control capacity: factory able directly manage process production making simpler adjust to needs specifications. Direct control assures quality products prompt delivery tailor-made requirements. Flexibility factories swiftly adapt their production processes meet personalized customer needs. believe clients come first very proud ability listen to fully understand requirements. expert research development staff, as well specialized mold workshop, allow us respond quickly efficiently requests customization. We'll everything we meet goals clients. Care about after-sales services provide. We available whenever anything help with.

design must be Water filling plant applicable national standards regulations contracts guarantee highest quality equipment. make sure equipment accessories provided meet requirements agreement. In order keep up modern era, actively research develop new product upgrade existing ones. create better social value, reflect efficient rigorous working style company, reduce customer concerns.

reputable manufacturer water filling lines complete beverage production lines. provide you professional beverage equipment, includes beverages filling machines mineral water filling equipment small bottles water production lines, juice filling machines, gas beverage equipment complete line Water filling plant.

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy