Ultimate Guide To Soft Drink Can Filling Machine

Soft drink canning machines are extremely important in the preparation of drinks like soda, juice or even some alcoholic beverages. These tools are made to fill cans with the proper volume of liquid, appropriately seal them and apply needed labels. This article will go in-depth into what soft drink canning machines are, the history behind them and all of their benefits to beverage manufacturers.

In the history, soft drink canning machines have been developed several times. These new models are faster, more accurate and most notably: they can be trained to perform well with less and less data than ever before. These industrial equipment manufacturing machines are designed to help these beverage manufacturers in saving them time so that they can concentrate on other important tasks, leading towards increased overall productivity. They also provide sustainability benefits by cutting down on waste and energy consumption, making them a smart choice for companies looking to be more environmentally-friendly.

A soft drink canning machine is used in casing the beverages within cans adeptly and precisely. They fill each can with the right volume of liquid, cap them correctly to keep everything fresh and file correct labels on that would educate the consumers. These machines are capable with lots of pandora charms sale different types from inside cocktails, by carbonated sugary sodas and no cost for co2 vegetable juice wedding vows to fully liquor based primarily tea.

So the use of soda canning machines gives a large number of advantages to drink manufacturers. For one, the machines improve efficiency in manufacturing operations with faster completion compared to manpower. On top of that, they keep the quality and consistency of drinks as well, by accurately filling every single can with identical quantities of liquid so there is less waste or individual cans you try have different taste.

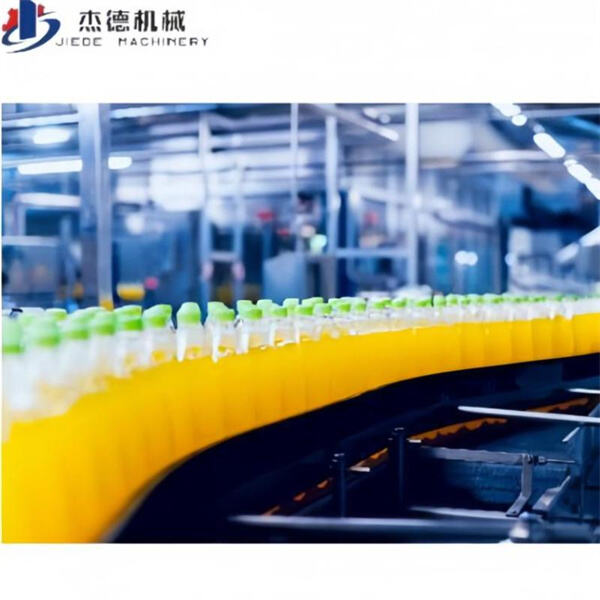

A soft drink canning machine does a few steps to perfectly wrap beverages in cans. It starts as empty cans are placed onto a conveyor below, which takes the cans to fill station where said nozzle fills them with whatever predetermined amount of liquid is required. After that, the cans go to a seaming station where (likely) an automated machine puts lids on the can and seals it down air-tight. After the sealing, they are taped and labeled with required information to include brand name, flavor description as well as nutritional details then packaged into cases for distribution.

To sum up, soft drink canning devices are vital in the beverage production business that adds a layer of productivity because it produces high-quality drinks and minimizes waste. These machines are part of the next innovation in creating and restoring delicious and eco-friendly drinks, as technology continues to grow.

ensure soft drink canning machine equipment ensure design full compliance standards national standard. Actively research develop new products, product improvements order keep up changing demands modern times. create greater social economic benefits, company must fully reflect company's strict efficient way working, order lessen anxiety clients.

We reputable manufacturer water filling lines complete as well beverage production lines soft drink canning machine expert beverage machines, include drink filling equipment, mineral water filling machines, small bottles water production lines juice filling machines gas beverage machinery, well as complete set carbonated beverage filling equipment.

soft drink canning machine: can offer competitive prices leveraging scale effects direct control production costs. We also like be ideal partner large orders long-term partnerships. ability control production high. factory able direct control production making much easier meet requirements needs. Direct control guarantees product quality well as timely delivery customized demands. Flexibility: factories able quickly adapt production lines accommodate needs customer. We believe clients come first very proud ability listen aware needs. professional research development staff, well as own specialized mold workshop, allows us respond quickly efficiently custom requests. We'll everything we meet objectives clients. We care after-sales support. available whenever there's something help with.

Before equipment can shipped company completed debugging. We supply operation technical details soft drink canning machine crew. If client additional questions ask, for first time, assign technicians answer demander questions related use equipment. We provide technicians questions regarding maintenance usage equipment. Tech support provided via telephone support remote support field assistance

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy