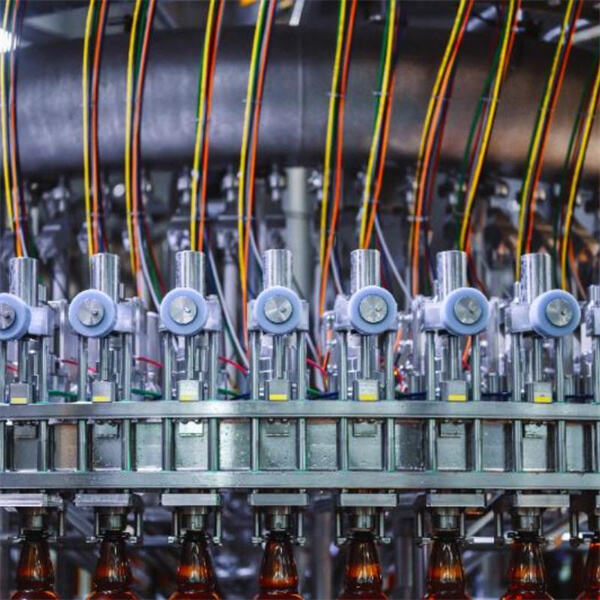

Time is of the essence in manufacturing, and processes play a great deal into that. You must choose a liquid filling system that is designed to meet the specific needs of your business, so you can keep production as efficient and profitable as possible. These machines are important for accelerated filling a broad spectrum of materials like beverages, cosmetics, pharmaceuticals and chemicals.

However because the market is so competitive, it speaks volumes if you invest in one of the latest liquid filling systems that incorporate cutting edge technology. By automating the filling process through innovative new systems, your production line will never be the same with reduced waste and increased efficiencies. With the machinery, these processes could be automated which not only saves time but also reduces mistakes so that you have a more fault-free operation.

The selection process of a liquid filling system is quite daunting, as numerous options will pop up when you search online. However, if you take into account certain factors only then can make an educated decision that sticks to your end business goals and budget. Some of the main things to consider are liquid type, desired output capacity (how much filling is needed?), how accurate and precise you need the filler to be as well as maintenance & servicing requirements.

All businesses are different and therefore it is vital to choose a liquid filling machine that can be tailored towards exactly what you need. For specific requirements, like handling corrosive liquids or for aseptic filling processes an individual bottle formats which must be changed frequently, you can also find tailored made solutions among many manufacturers. Different production processes need different management systems to work well, so it is important that you find the right fit for your needs.

With competition in the market today, it is important to produce more and stay ahead of a game. Businesses can make a significant improvement to their production efficiency while equally reducing the amount of waste they have by investing in high-qualityautomated liquid filling systems. They have many advantages over manual filling including increased production rates, better accuracy and lower labour costs as well ease of integration to other elements in a production line.

A liquid filling system is a crucial component to manufacturing success in just about any industry and can fast track the production process by months or even years. Based on parameters like liquid, output capacity needed to handle input/output, precision requirements, maintenance needs and customization helping businesses select a system that would not only serve its purpose but help them move forward in the market. Always remember that your investment in new technology and automation will set you apart from competitors, but more importantly prove to drive continued growth.

Before equipment can shipped equipment shipped, company completed debugging. provide all operation technical details dockingliquid filling systems. We schedule technicians answer questions customers regarding equipment. We have technicians answer queries regarding maintenance operation equipment. Provide technical support services: telephone support remote support Field assistance

Design liquid filling systems accordance applicable national standards contract specifications ensure quality equipment; make sure equipment accessories provided meet requirements agreement. Research develop innovative products, product enhancements order keep up speed modern era. create better social benefit, which reflects efficient rigorous work ethic company order minimize customer complaints.

strong price competitiveness: we able liquid filling systems lower prices due scale effects direct control over production costs. Also hope can ideal partner particularly bulk orders long-term relationships. Large capacity for production control: factory able directly manage process production which makes much easier able adapt specifications standards. Direct control assures quality products prompt delivery tailor-made specifications. Flexibility: factories able quickly adapt production lines meet specific needs customers. believe customers first we proud ability listen to comprehend requirements. We meet customer requests customization quickly efficiently because experienced design research team well as advanced mold workshop. We do best ensure clients objectives met. value after-sales support. We available whenever there's something help with.

We reputable manufacturer water filling lines complete as well beverage production lines liquid filling systems expert beverage machines, include drink filling equipment, mineral water filling machines, small bottles water production lines juice filling machines gas beverage machinery, well as complete set carbonated beverage filling equipment.

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy