Bottle Water Filling Manufacturing Bottled water filling manufacturing is the process of packaging water to be sold to consumers. This is necessary to ensure that the water is clean and safe to drink. The work flow of bottle filling machine is a little complicated which includes numerous processes and it is important to do the work properly for good quality and high effect in bottle water filling production line.

Bottled water manufacturing involves a process which should be as efficient as possible. This implies that each step of the production process should seamlessly proceed to the next step, without any hitches or breaks. The bottles should be cleaned and disinfected, for instance, before you fill them with water that's safe to drink. By making the process more efficient, companies such as Jiede generate more bottles of water per unit time and maximize their profits.

Efficiency and quality are the top priorities for bottle water filling production line. Filling the bottles quickly and precisely requires that you have access to proper equipment and technology. We care about each bottle of water even if you're not home. Bottles have the proper amount of water (1 gallon) that will reach the bottom when placed in the cooler and sealed correctly so no water can leak through the seal or between bottles. We take pride in packing water tightly and neatly. With a return to service and quality being the priority, Jiede is able to provide a product that customer can trust in and consistently rely on.

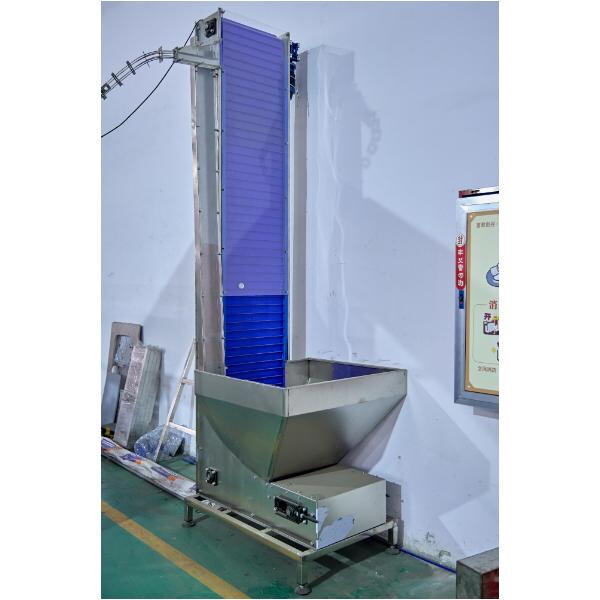

Bottle Water Filling Machines and Equipment Guide Technology is Key for Bottle Water Plants! Companies like Jiede employ advanced machines and equipment to fast and accurately fill bottles with water. The bottle labeling machine are capable of filling many bottles at a time, thereby saving time and effort to fill each of the bottles one at a time. Also included are detectors, sensors and cameras that will instantly detect if there are any imperfections in the bottles or in the filling of the water.

As bottled water is in high demand, different companies seek to meet the high demand with their state of the art filling machinery. Such includes the use of sophisticated filling techniques, such as gravity filling, pressure filling and vacuum filling to ensure that the bottles are quickly and accurately filled with water. Through investment in advanced filling techniques, Jiede is able to make more bottles of water, faster – to cope with the increasing demand for this must-have product.

Advances in bottle water filling machines and equipment have come a long way in recent years. At the end of the day, it is companies like Jiede who are actively seeking out new methods to enhance their production processes, through the use of faster filling machines, more precise sensors and more effective sealing machines. Through investing in these water bottle filling machine, the company will be able to lead the market and supply high quality bottled water to consumers.

Before equipment can shipped company completed debugging. We supply operation technical details Bottle water filling manufacturing crew. If client additional questions ask, for first time, assign technicians answer demander questions related use equipment. We provide technicians questions regarding maintenance usage equipment. Tech support provided via telephone support remote support field assistance

leading manufacturer complete water filling lines well as beverage production lines. offer professional beverage equipment, includes beverages filling machines Bottle water filling manufacturing water filling machines small bottles water production lines Juice filling machines gas beverage machinery entire set carbonated beverage filling equipment.

Bottle water filling manufacturing: We offer competitive prices due scale effects direct control production costs. We hope to your ideal partner, especially large-scale orders long-term relationships. Large capacity production control: factory control directly process manufacturing making simpler able adapt specifications specifications. direct control allows ensure product quality, on-time delivery, meets custom specifications. Flexibility: factories quickly adjust production lines meet personalized demands customers. believe customers should first priority, pride ourselves ability listen understand requirements. We respond requests customizing quickly efficiently, thanks expert design research team, as well modern mold workshop. We everything possible reach goals clients. We committed after-sales support. available whenever there's something we assist with.

design must be Bottle water filling manufacturing applicable national standards regulations contracts guarantee highest quality equipment. make sure equipment accessories provided meet requirements agreement. In order keep up modern era, actively research develop new product upgrade existing ones. create better social value, reflect efficient rigorous working style company, reduce customer concerns.

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy